Production

Our production lines are based on a selection of quality machinery to offer our customers a full service concept

We Add Value To All Products

DanThai Machinery, since its inception in 2010, has emerged as a beacon of excellence in the realm of machinery production. Our journey began over a decade ago with a clear vision: to not only create products but to add indisputable value to every item that passes through our hands. This ethos has been the cornerstone of our growth and success, firmly establishing us as leaders in our field.

DanThai Machinery, since its inception in 2010, has emerged as a beacon of excellence in the realm of machinery production. Our journey began over a decade ago with a clear vision: to not only create products but to add indisputable value to every item that passes through our hands. This ethos has been the cornerstone of our growth and success, firmly establishing us as leaders in our field.

The Core of DanThai: Our Exceptional Team

At the heart of our operations is an exceptionally competent group of employees, each bringing their unique skills and expertise to the table. This team is the lifeblood of DanThai Machinery, a group that has grown and evolved with the company. Some of these dedicated professionals have been with us since our founding days, embodying the spirit and commitment that DanThai stands for. The average tenure of our employees is over four years, a testament to their dedication and belief in our vision.

The diversity in experience and expertise among our team members enables us to approach each project with fresh eyes and innovative solutions. From design to the finished product, our team is committed to excellence. This unwavering dedication to quality and innovation is what sets DanThai Machinery apart in the competitive landscape of machinery production.

Experience and Expertise in Diverse Materials

Our expertise extends to working with a broad spectrum of raw materials. This includes aluminium, hardened steel, steel, stainless steel, and more, showcasing our versatility and adaptability to various industry needs. Our machinery base is meticulously composed to meet almost all demands from many different industries. Over the years, we have supplied machine components and parts to a wide array of sectors, each with its unique requirements and challenges.

Collaboration with Customers: A Partnership Approach

At DanThai Machinery, we believe in working in close collaboration with our customers. This partnership approach allows us to assist them in developing not just designs and manufacturing solutions, but also strategies for cost reduction. Whether the requirement is for low volume or high-volume production, we ensure that our solutions are cost-effective, with quick turnaround times and uncompromised quality.

Our customer-centric approach has enabled us to build long-lasting relationships based on trust, reliability, and mutual growth. We understand that each customer has unique needs, and we strive to provide tailored solutions that meet these specific requirements.

Leadership and Management: The Danish Connection

Our Production Department is spearheaded by a Danish Manager, a seasoned professional with over 30 years of experience in the technical industry. His extensive knowledge and leadership skills are pivotal in overseeing all functions of the production process. This includes planning, design of parts and components, manufacturing, and systematic maintenance of our machinery.

The manager’s expertise is not kept in isolation; it is disseminated across the team, ensuring that every member is equipped with the knowledge and skills required to excel in their respective roles. This transfer of knowledge and experience is crucial in maintaining the high standards of quality and efficiency that DanThai Machinery is known for.

Quality and Efficiency: Our Primary Focus

The primary focus of this segment of our organization is to produce high-quality parts and components as efficiently as possible. This efficiency is key to securing competitive prices for our customers without compromising on quality. Management pays special attention to Research & Development, ensuring that our production flow remains updated and capable of meeting the evolving expectations of our customers. High-quality products and adherence to promised delivery dates are not just goals but commitments we make to each of our clients.

A Global Reach: Serving Diverse Industries

Our expertise in machinery production has been recognized both locally and internationally. We have had the privilege of supplying industrial machine parts and components to various industries. This includes Construction Machinery, Food Processing Machinery, Pharmaceutical Machinery, Material Handling Machinery, Packaging Machinery, Mining Machinery, Farm Equipment, Printing Machinery, and Woodworking Machinery, to name a few.

Each industry presents its unique challenges and requirements, and our ability to adapt and cater to these diverse needs speaks volumes about our flexibility and commitment to quality.

Full-Service Concept: Our Promise to Customers

Our production lines are meticulously designed and equipped with a selection of quality machinery. This setup enables us to offer our customers a full-service concept. From the initial design phase to the final product, we ensure that every step of the process is handled with utmost care and precision. Our goal is not just to meet customer expectations but to exceed them, providing value that transcends the mere functionality of the products we create.

Examples of industries local and international, we have supplied with industrial machine parts and components:

Construction Machinery, Food Processing Machinery, Pharmaceutical Machinery, Material Handling Machinery, Packaging Machinery, Mining Machinery, Farm Equipment, Printing Machinery and Woodworking Machinery.

Our production lines are based on a selection of quality machinery to offer our customers a full service concept.

our full-service machinery park

CNC Machine center 4-axis with rotatable table (Milling)

- Hardford /model VMC-1271

- Table size 1200x500mm

- Made in Taiwan by She Hong Industial Co.,Ltd.

CNC Vertical Machining center 3-axis (Milling)

- HAAS /model VF-2SE

- Table size 368x914mm

- Made in USA by HAAS Automation,Inc

CNC Vertical Machining center 3-axis (Milling)

- NEWAY /model VM740H

- Table size 750x420mm

- Made in Neway CNC equipment (Suzhou)Co.,Ltd

CNC Vertical Machining center 4-axis with rotatable table (Milling)

- NEWAY /model VM1150S

- Table size 1100x520mm

- Made in Neway CNC equipment (Suzhou)Co.,Ltd

CNC Vertical Machining center 3 axis (Milling)

- HAAS /model VF-4-SE

- Table size 1321x457mm

- Made in USA by HAAS Automation,Inc

CNC Vertical Machining center 3-axis (Milling)

- HAAS /model VF-2SE

- Table size 368x914mm

- Made in USA by HAAS Automation,Inc

Machine turning center with rotary tools (Turning)

- Doosan /model puma 240MB

- Work size OD 250x500mm

- Made in Korea by Doosan Infacore

CNC Lathe Machine (Turning)

- HAAS /model SL-20T

- Work size OD 250x500mm

- Made in USA by HAAS Automation,Inc

CNC Lathe Machine (Turning)

- HAAS /model ST-10

- work size OD 200x300mm

- Made in USA by HAAS Automation,Inc

Flat-Bed CNC Lathe Machine (Turning)

- ANGLE /model FL12E/1500

- Work size OD 400x800mm

- Made in Thailand by Angle CNC Equipment (Thailand) Co.,ltd

Flat-Bed CNC Lathe Machine (Turning)

- ANGLE /model FL12E

- Work size OD 400x800mm

- Made in Thailand by Angle CNC Equipment (Thailand) Co.,ltd

Band Saw (Manually operated)

- Bomar/ model Ergonomic 30.250G

- Work size 250x300mm

- Made in Czech republic by Bomar,spol.sro

Full-automatic Band saw

- Timeway/ model FAB320

- Work area 230X300X6000MM

- Made in China by TIMAC

processes and services we outsource to reliable suppliers

- WIRE CUT / EDM

- LASER CUT / WATER JET CUTTING

- SHEET BENDING

- NICKEL PLATING

- ZINC PLATING

- ANODIZING

- PAINTING

- BLACK OXIDE

- HEAT TREATMENT

- GRINDING

In view of today’s competitive picture, outsourcing is an efficient and effective alternative. During more than 10 years we have succeeded in creating a solid network of certified suppliers enabling us to offer customers a full service concept.

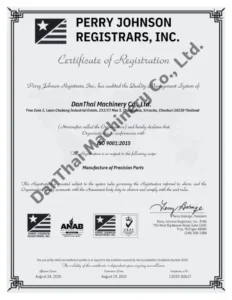

Quality assurance and policies

- Ensure materials, products and processes are fit for purpose and meet relevant quality standards.

- We do not take illegal or unethical actions

- We do not approve of corruption of any kind

- We do not approve violent actions

- We respect International Labour Standards on Child labour

- We believe in sustainability leadership